Build, maintain, and troubleshoot

Robots work to make life easier for humans and help to streamline and increase production. But like all machines, they need someone to build, program, maintain, and fix them. The robotics technician provides expert service throughout the life of the robot and prolongs its use.

Robotic technicians generally work in industrial manufacturing and supply chain/logistics facilities or work with engineers and designers to assemble and test robots. Robot technicians who work in industrial manufacturing and supply chain facilities are responsible for maintaining the robot’s electrical and mechanical systems and troubleshooting when there are issues. Robot technicians can also install robots at plant sites, ensuring the automation control systems are working correctly.

If becoming a robotic technician interests you, and you want to work with engineers and designers, you will need an understanding of computers, electrical and electronic systems, sensors, and automation control systems.

An associate degree or technical certificate in Electrical, Mechanical or Mechatronics engineering technology is required to become a robotic technician. Most engineering technology programs take two years to complete and include coursework in robotics programming, conveyor systems, and computer networking and integration. Work experience in mechatronics or a Mechatronics certification can also be sufficient.

Most academic programs include coursework in motion programming, conveyor systems, and computer networking and integration and take approximately two years to complete.

Using Robots to Streamline the Supply Chain

Robots make manufacturing more efficient by performing repetitive tasks and are designed to work at a faster pace while maintaining a safe environment. The robotic technician ensures that robots operate at peak performance, which is crucial in the supply chain.

Supply chains can be a complex network and robot technicians ensure that the manufacturing floor never stops making products and meets production requirements and shipping deadlines. Many vital tasks in the supply chain, like moving products through a warehouse, often rely on robots and robot technicians.

Skills Needed to Become a Robotic Technician

Some of the essential foundational skills needed to become a robotic technician include:

- Manual dexterity

- Mechanical skills

- Knowledge of repairing machines and systems

- Spatial sense

- Software programming

- Critical thinking

- Creative problem solving

- Communications

Veterans often possess many of the skills that are a good fit for careers in supply chain automation. Robotics technician is one of many jobs for veterans that align with military training.

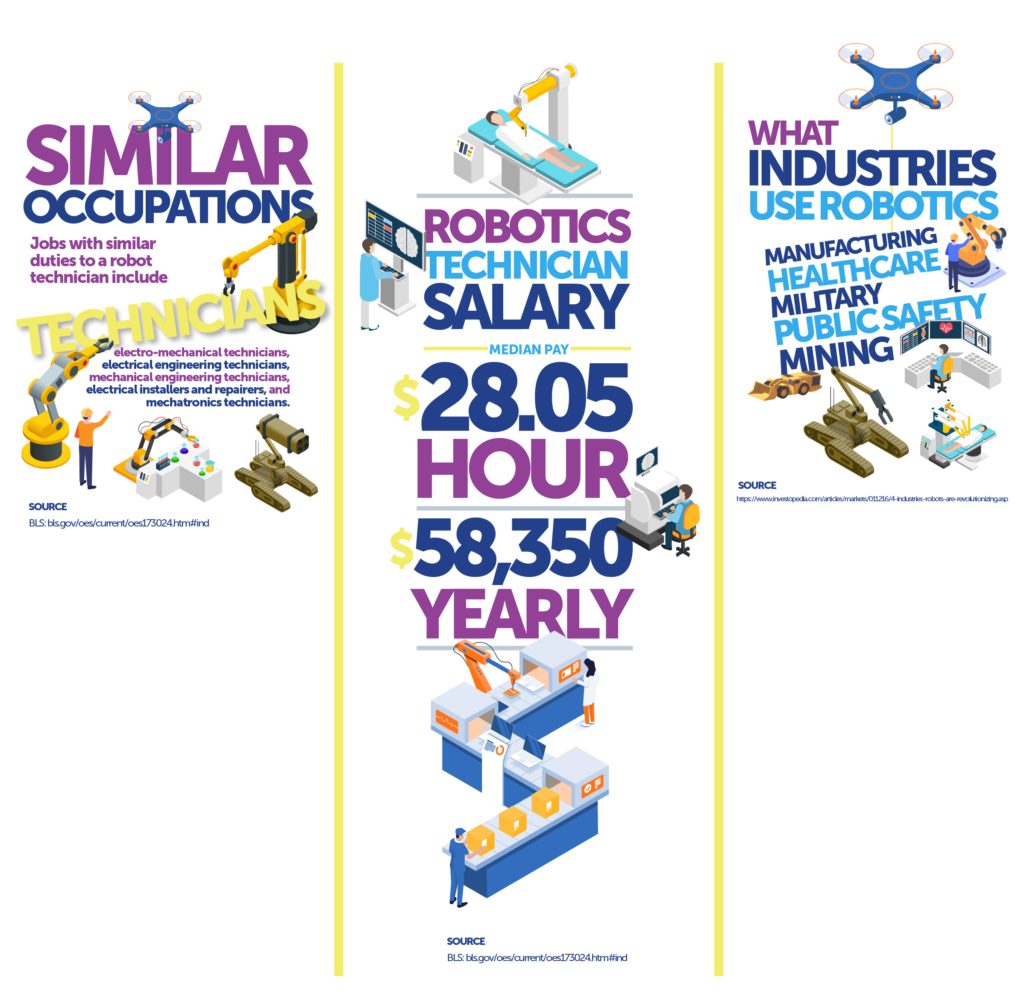

The U.S. Bureau of Labor Statistics (BLS) counts robotics technicians among electro-mechanical technicians. Median pay as of 2019 was $58,350 per year or $28.05 per hour.

Source: BLS

Similar Occupations to Robotics Technician

Jobs with similar duties to a robot technician include electro-mechanical technicians, electrical engineering technicians, mechanical engineering technicians, electrical installers and repairers, and mechatronics technicians.

Source: BLS

What Industries Use Robotics?

Manufacturing, healthcare, military and public safety, and mining are four industries that robots are revolutionizing.

Source: Investopedia